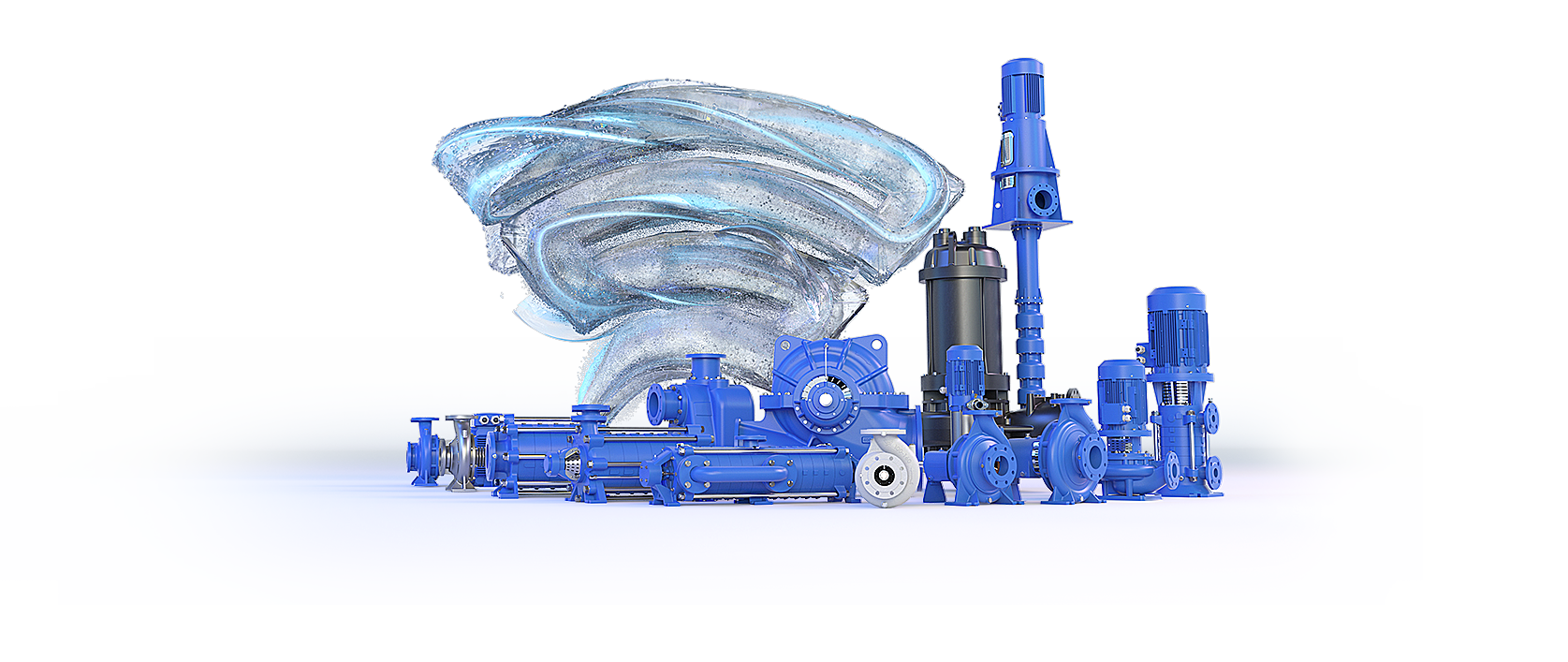

Pump Selection

choose the pump that suits your needs or project

psp.sempapompa.com visit the address.