Make a Choice

Make a Choice

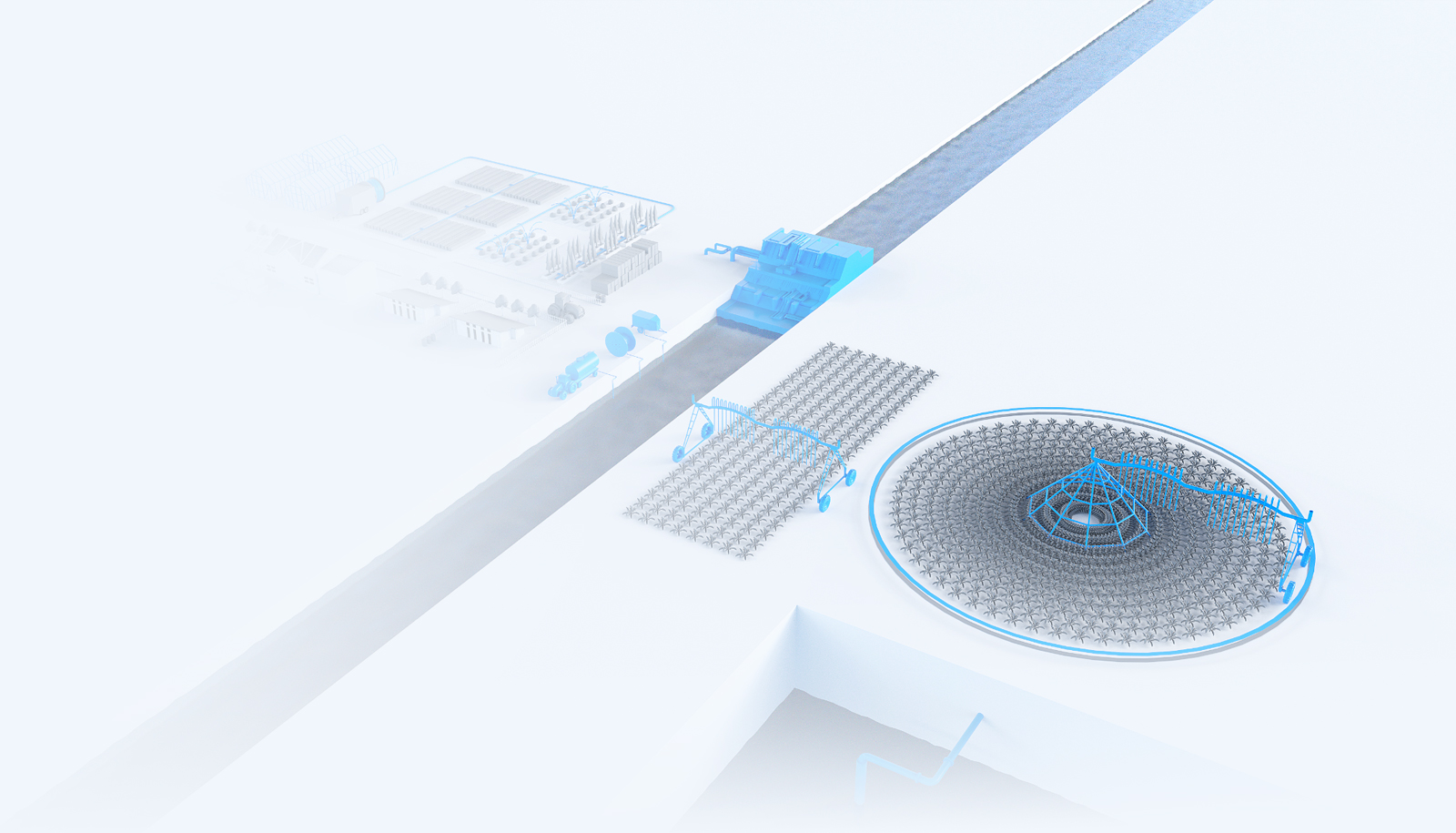

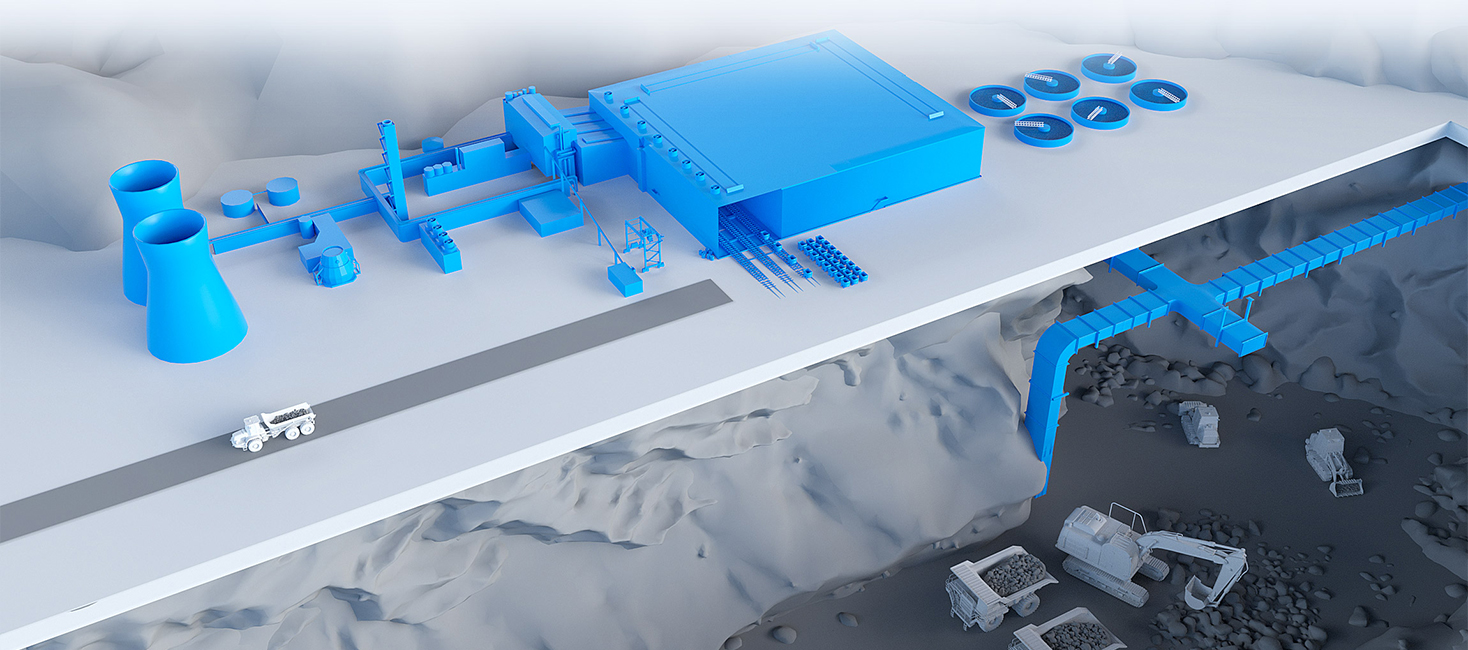

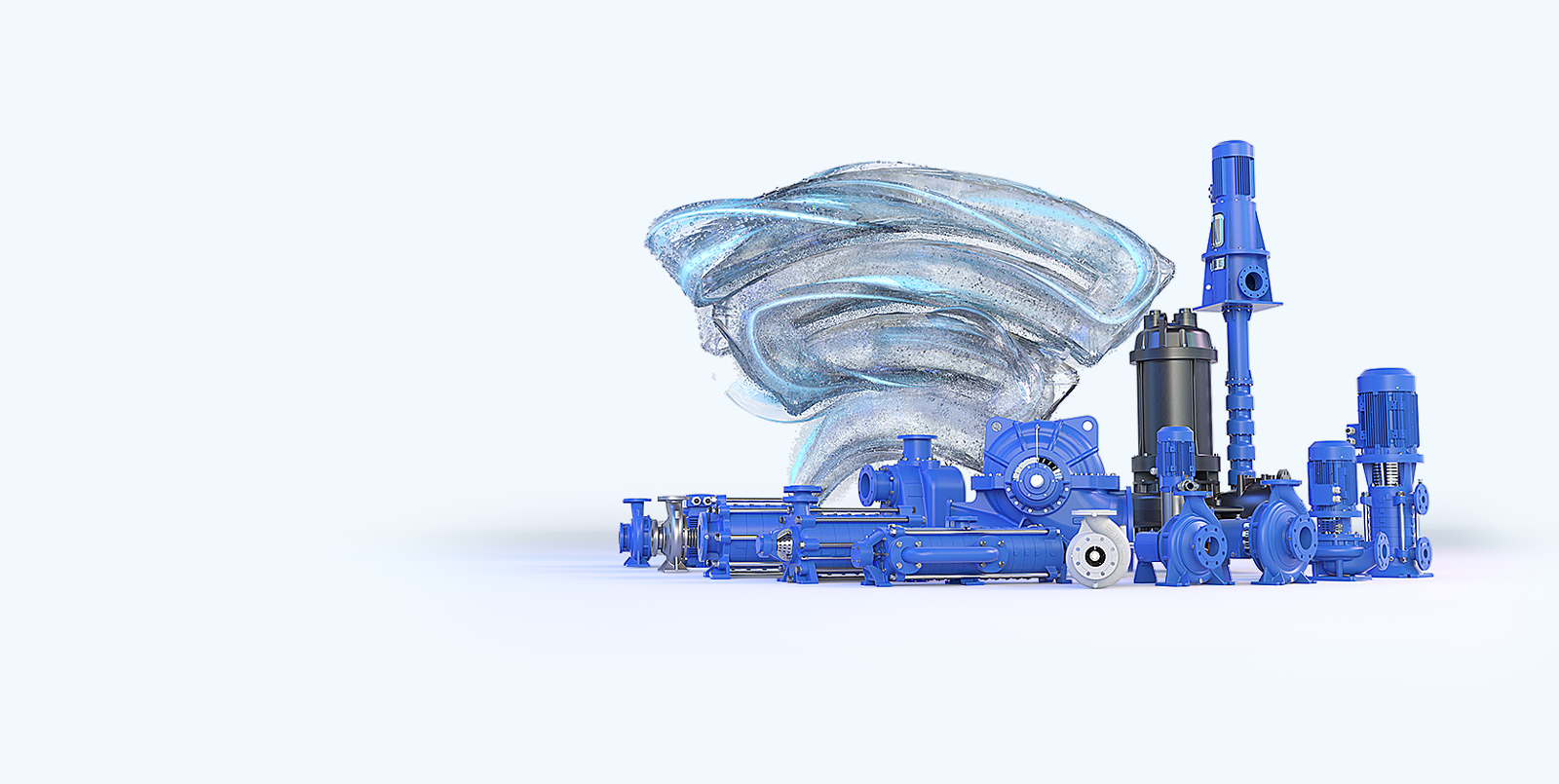

Industrial pumps are mechanical devices used for transporting, pressurizing, and dosing various liquids. There are many types of industrial pumps with different operating principles and designs available.

Each pump has its own unique advantages and disadvantages, and the most suitable pump for a particular application depends on the characteristics of the liquid to be transported, the desired flow rate and pressure values, and other factors. Industrial pump types are used in a wide range of industrial and commercial applications.

The main application areas are as follows:

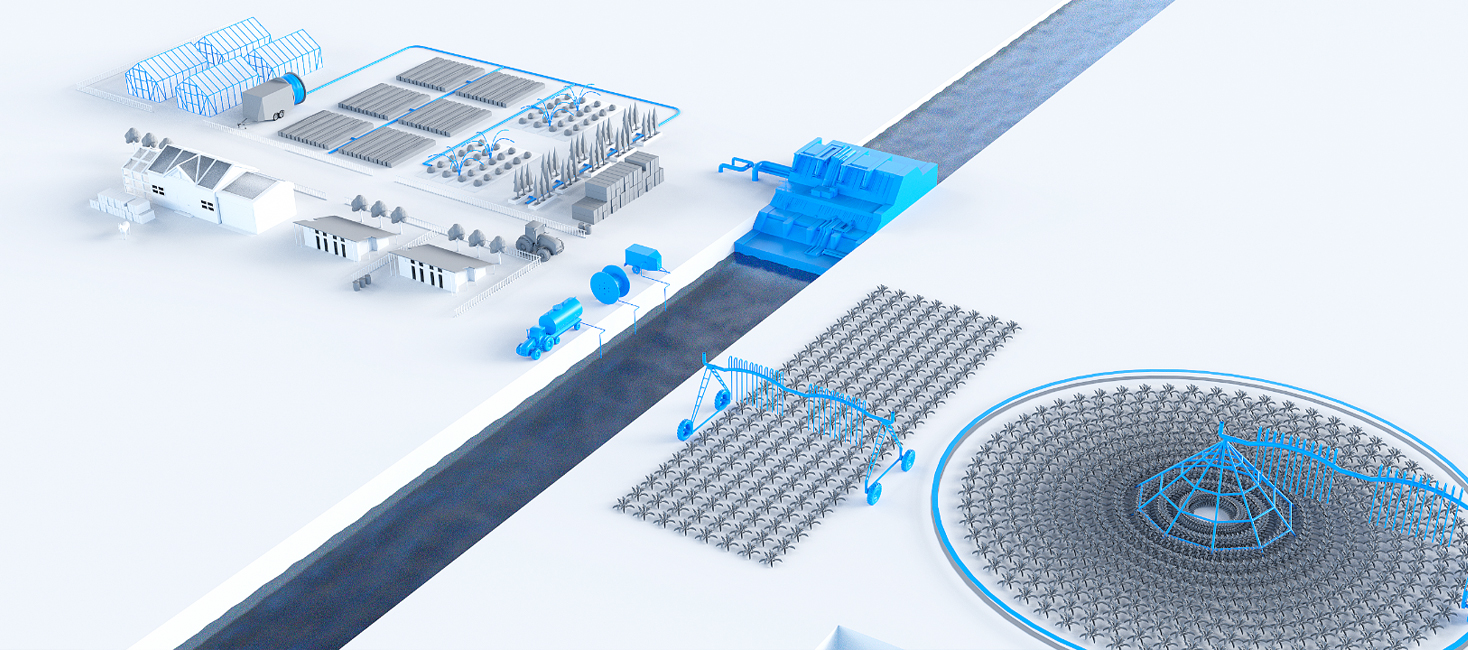

When choosing an industrial pump, there are many factors to consider. The most important factors are as follows:

Sempa Pompa offers a wide range of high-quality industrial pumps to meet every demand, need, and budget, providing customers with impeccable service and offering the best options for every pump type sought after.

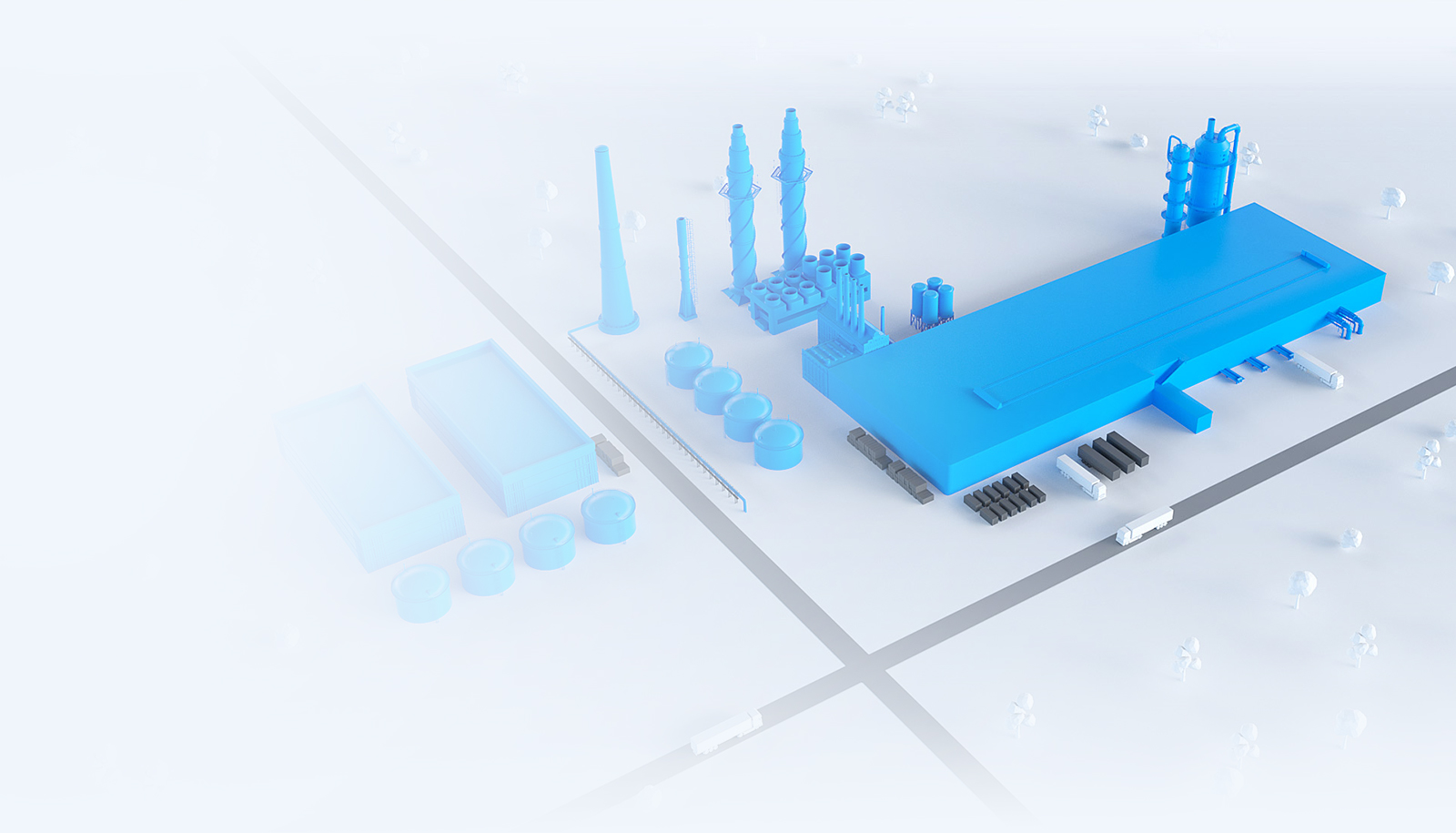

Industrial pump manufacturers are companies that design, produce, and sell pumps used in various sectors. These companies particularly offer a wide range of pump types tailored to different needs and applications.

Sempa Pompa, on the other hand, is one of the leading names in the industry, producing high-quality and reliable pumps for all kinds of industrial applications. Operating for many years, Sempa Pompa provides its customers with the most suitable solutions through its extensive product range and expert team.

Some of the advantages offered by Sempa Pompa include:

We provide services throughout Turkey.

Sempa Pompa is one of Turkey's leading pump manufacturers, offering a wide range of industrial pump solutions tailored to every sector and need. The prices of industrial pumps vary depending on the type, capacity, brand, material, and other technical specifications of the pump.

At Sempa Ppmpa, we have a broad price range to offer pump solutions that fit every budget and requirement. We provide personalized pricing for each customer at Sempa Pompa. Our pricing process is as follows:

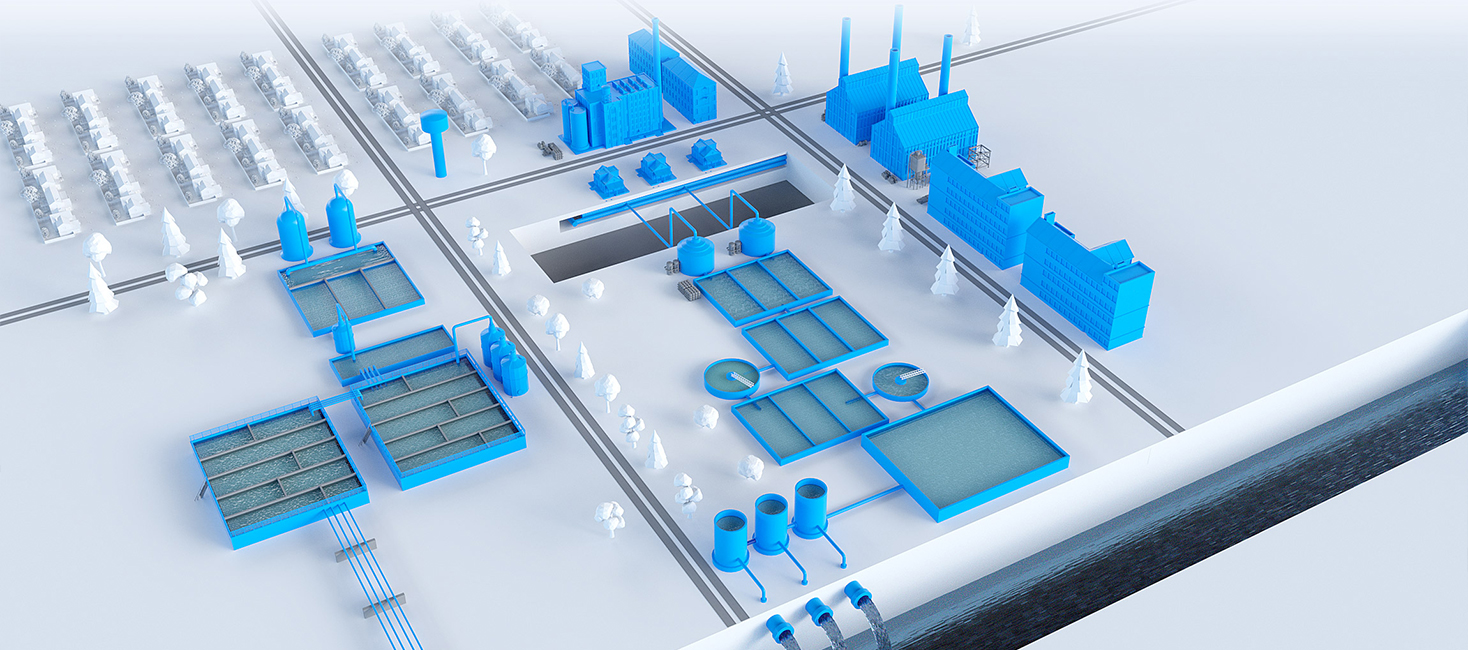

Pumps are mechanical devices used to transport liquids from one point to another. In industrial areas, various types of pumps are used to meet the different pressure and flow requirements of various liquids. As a result, there are many different types of industrial pumps available.

Especially the most commonly used types of industrial pumps are as follows:

Centrifugal pumps are the most common type of pump that pumps liquids by rotating a impeller. When the impeller rotates, the liquid is pushed outward by centrifugal force, creating a flow towards the pump's outlet.

Centrifugal pumps are versatile pumps used in various applications. Some advantages of centrifugal pumps include:

Booster pumps are a type of centrifugal pump used to increase water pressure. They are commonly used for water supply in homes and small businesses. Booster pumps work in conjunction with a pressure tank.

When the pump fills the tank with water, the pressure in the tank increases. This pressure is then used to distribute water to taps and other water fixtures.

Fire pumps are high-capacity centrifugal pumps used in fire suppression systems. They are used to provide high-pressure water to fire hoses and sprinklers. Fire pumps can be either electrically or diesel-powered. Some advantages of fire pumps include:

Wastewater pumps are a special type of centrifugal pump used to pump wastewater and sewage. These pumps are typically used in sewer systems and treatment plants. Wastewater pumps are designed to handle solid materials and corrosive liquids.

Some advantages of wastewater pumps include:

Submersible pumps are pumps that are submerged underwater and pump liquid upwards. They are commonly used in wells, water tanks, and wastewater pits. Submersible pumps are designed to operate in contact with water. Some advantages of submersible pumps include:

End suction pumps are centrifugal pumps that draw fluid from the end of the pump. They are commonly used in irrigation, drainage, and chemical processing. End suction pumps require a pump that is primed and pre-filled with air removed.

Double suction pumps are centrifugal pumps that draw fluid from both sides of the pump. They are generally used in high-capacity and high-pressure applications. Double suction pumps provide more balanced operation and higher efficiency.

Circulation pumps are used to circulate fluid in a closed circuit. They are commonly used in heating and cooling systems, as well as in the recirculation of hot and cold water and in industrial processes. Circulation pumps enhance system efficiency by ensuring fluid flow and improving heat transfer within the system.

Boiler pumps are a specialized type of centrifugal pump used to circulate water in steam boilers. Designed to withstand high pressures and temperatures, boiler pumps play a crucial role in ensuring the proper functioning of the boiler and achieving the desired steam capacity.

Vertical turbine pumps are a type of turbine pump that is vertically mounted and pumps fluid upwards. They are commonly used in water wells, drainage, and wastewater treatment plants. Vertical turbine pumps are high-capacity and efficient pumps.

Hot oil pumps are a specialized type of centrifugal pump designed for use at high temperatures (up to 350°C). They are commonly used in thermal power plants, food processing facilities, and asphalt plants. Hot oil pumps are manufactured from special materials that can withstand high temperatures, and ensuring tight sealing is crucial.

Geothermal pumps are a specialized type of pump used to circulate hot water from geothermal sources. They are typically used in geothermal power plants and heating and cooling systems. Geothermal pumps are made from materials resistant to high corrosion and are resistant to abrasive fluids.

Stainless steel pumps are a specialized type of pump used in applications where corrosion resistance is essential. They are commonly used in food processing plants, chemical plants, and in pumping seawater. Stainless steel pumps are made from stainless steel and can be used with a wide variety of liquids. Some advantages of stainless steel pumps include:

Monoblock pumps are centrifugal pumps where the motor and pump body are integrated into a single unit. They are known for being compact and easy to install. They are commonly used in irrigation, drainage, domestic water pressure boosting, and industrial applications.

In-line pumps are centrifugal pumps designed to be mounted directly in the pipeline. They are known for their compact size and require less space. They are commonly used in irrigation, drainage, building services, and industrial applications.

Diesel motorized pumps are centrifugal pumps driven by a diesel engine. They are known for their ability to operate in locations where there is no electrical grid. Diesel motorized pumps are particularly used in irrigation, drainage, flood control, and firefighting applications.