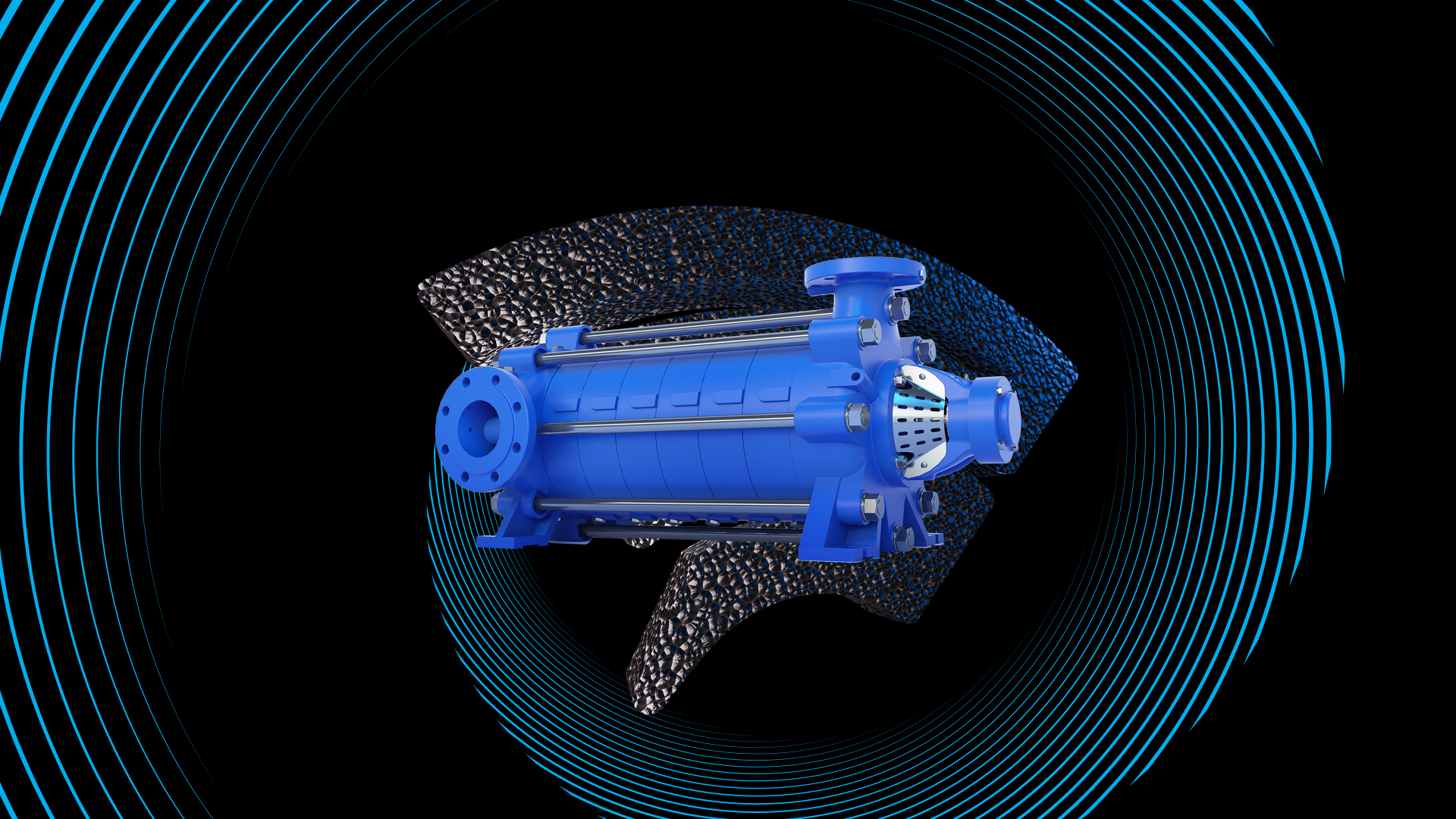

Corrosion is a common issue in industrial processes that can significantly reduce the lifespan of equipment. Pumps, particularly those used in liquid transport processes, are among the most susceptible equipment to corrosion. For this reason, pumps made from corrosion-resistant materials are critically important in many industries. In this blog post, we will explore corrosion-resistant pump materials and their various applications in detail.

Corrosion is defined as the deterioration of a material through its interaction with its environment. On metal surfaces, it typically occurs as rusting or wear due to reactions with oxygen and water. Corrosion not only shortens the lifespan of equipment but also leads to inefficiencies in production processes and even safety risks.

Various materials with different properties are used in the manufacturing of corrosion-resistant pumps. The most commonly used materials include:

Stainless Steel: One of the most frequently used materials due to its high corrosion resistance. Different alloys make it suitable for various corrosive environments.

Cast Iron: An economical material that performs well in acidic environments.

Bronze: Ideal for environments like seawater and saltwater.

Plastics: Materials like PTFE and PVC offer high resistance to abrasive chemicals.

Ceramics: A specialized material used in high-temperature and abrasive environments.

Chemical Industry: Stainless steel, plastic, and ceramic pumps are used for transporting acids, bases, and other chemicals.

Food Industry: Stainless steel and plastic pumps are preferred for transporting food products that require hygienic conditions.

Water Treatment: Bronze, stainless steel, and plastic pumps are utilized for handling aggressive liquids like saltwater and wastewater.

Energy Sector: Stainless steel and specially alloyed pumps are used in challenging conditions like seawater cooling systems and acid rain exposure.

Pulp and Paper Industry: Stainless steel and specially alloyed pumps are employed for transporting acidic and hot liquids.

Coating: Applying corrosion-resistant coatings to pump surfaces.

Sacrificial Anodes: Connecting the pump electrically to an anode to prevent corrosion.

Material Selection: Choosing appropriate materials based on the operating environment.

Regular Maintenance: Cleaning and lubricating pumps regularly to extend their lifespan.

Corrosion-resistant pump materials and applications are crucial for the efficiency and safety of industrial processes. Proper material selection and regular maintenance extend the life of pumps while reducing operating costs. In this blog post, we aimed to provide an overview of corrosion and corrosion-resistant pump materials. For more detailed information, consulting an expert is recommended.