Special Pump Types Used in the Energy Sector

The energy sector requires pumps at various stages, from production to distribution, for transporting and pressurizing liquids. The pumps used in this field must be capable of operating under challenging conditions such as high temperatures, corrosive liquids, and high pressure. In this article, we will discuss the pump types commonly used in the energy sector and their features.

Pump Applications in the Energy Sector

Thermal Power Plants:

- Feedwater Pumps: Operate at high pressure to feed water into boilers.

- Condenser Pumps: Used to condense steam exiting steam turbines.

- Sulfuric Acid Pumps: Employed in flue gas cleaning systems.

Nuclear Power Plants:

- Cooling Water Pumps: Used for cooling the reactor.

- Feedwater Pumps: Supply water to steam generators.

- Wastewater Pumps: Transport radioactive waste materials.

Hydroelectric Power Plants:

- Maintain water under high pressure in tunnels and pipes.

Oil and Natural Gas:

- Used in processes such as extracting, transporting, and refining crude oil and natural gas.

Renewable Energy:

- Geothermal Power Plants: Transport hot water.

- Biomass Power Plants: Pump liquids in various processes.

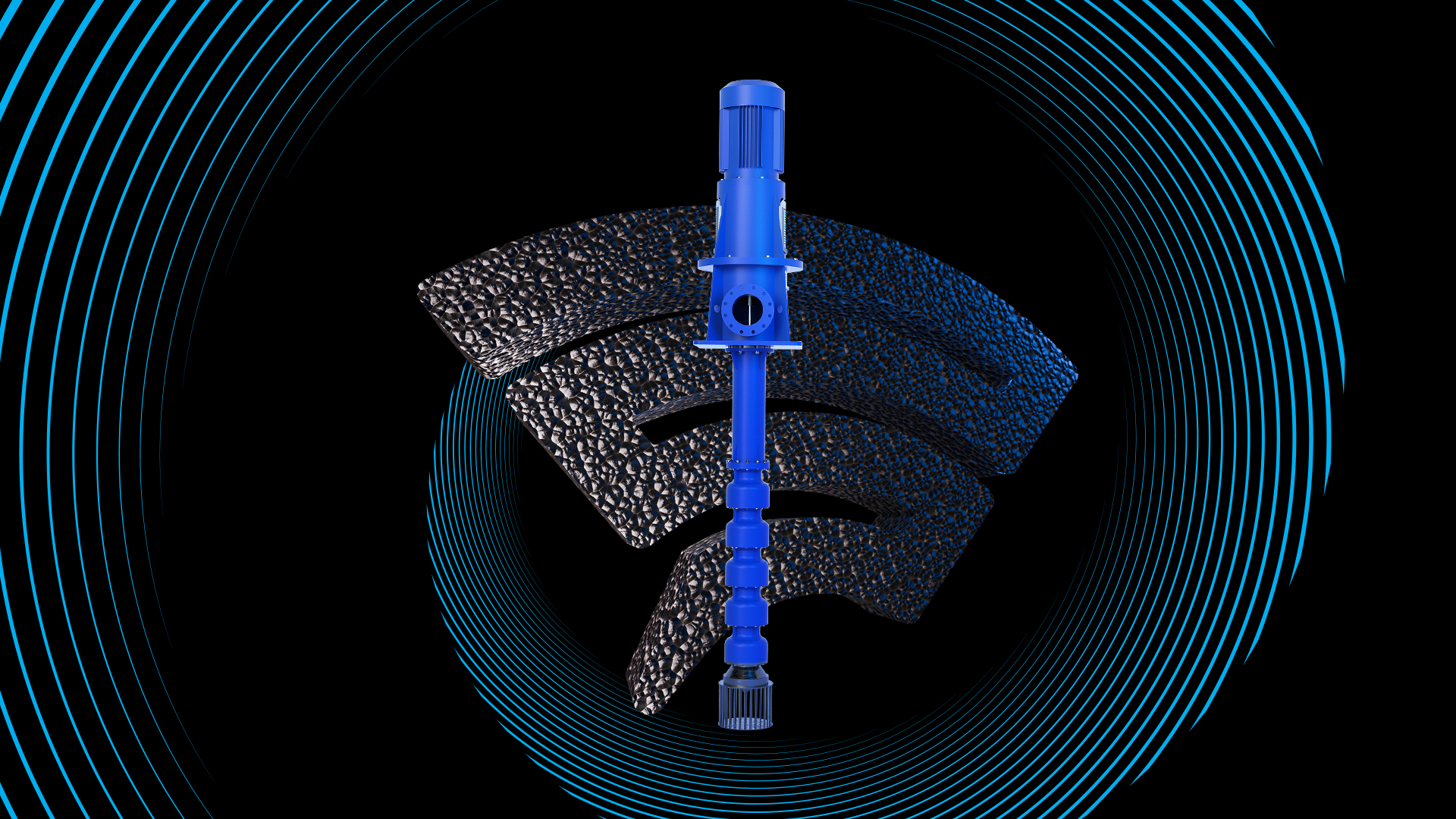

Special Pump Types Used in the Energy Sector

- Multistage Centrifugal Pumps: Designed with multiple stages to generate high pressure, commonly used as feedwater pumps.

- Diaphragm Pumps: Ideal for transporting abrasive, viscous, or solid-particle-containing liquids. Often preferred in chemical injection systems.

- Magnetically Driven Pumps: Eliminate sealing issues, making them suitable for hazardous or valuable liquids. Widely used in nuclear power plants and chemical facilities.

- Peristaltic Pumps: Excellent for precise dosing and hygienic applications. Used in chemical injection systems, as well as in the food and pharmaceutical industries.

- Axial Flow Pumps: Transport large volumes of liquid at low pressure. Frequently used in cooling water circuits.

- Screw Pumps: Suitable for viscous liquids and those containing solid particles. Commonly employed in the oil and gas industry.

Considerations When Selecting a Pump

- Liquid Properties: Viscosity, density, temperature, and corrosiveness of the liquid are key factors.

- Operating Conditions: Pressure, flow rate, temperature, and corrosion resistance impact the selection process.

- Energy Efficiency: Energy-efficient pumps are critical given today's high energy costs.

- Ease of Maintenance: The pump should be easy to disassemble and maintain.

- Material Selection: Materials used in pump construction should match the chemical properties of the liquid.

Pumps used in the energy sector must offer high performance and reliability. In this article, we explored the common pump types and their features in the energy sector. When selecting a pump, it’s essential to consider the factors mentioned above to ensure the right choice.