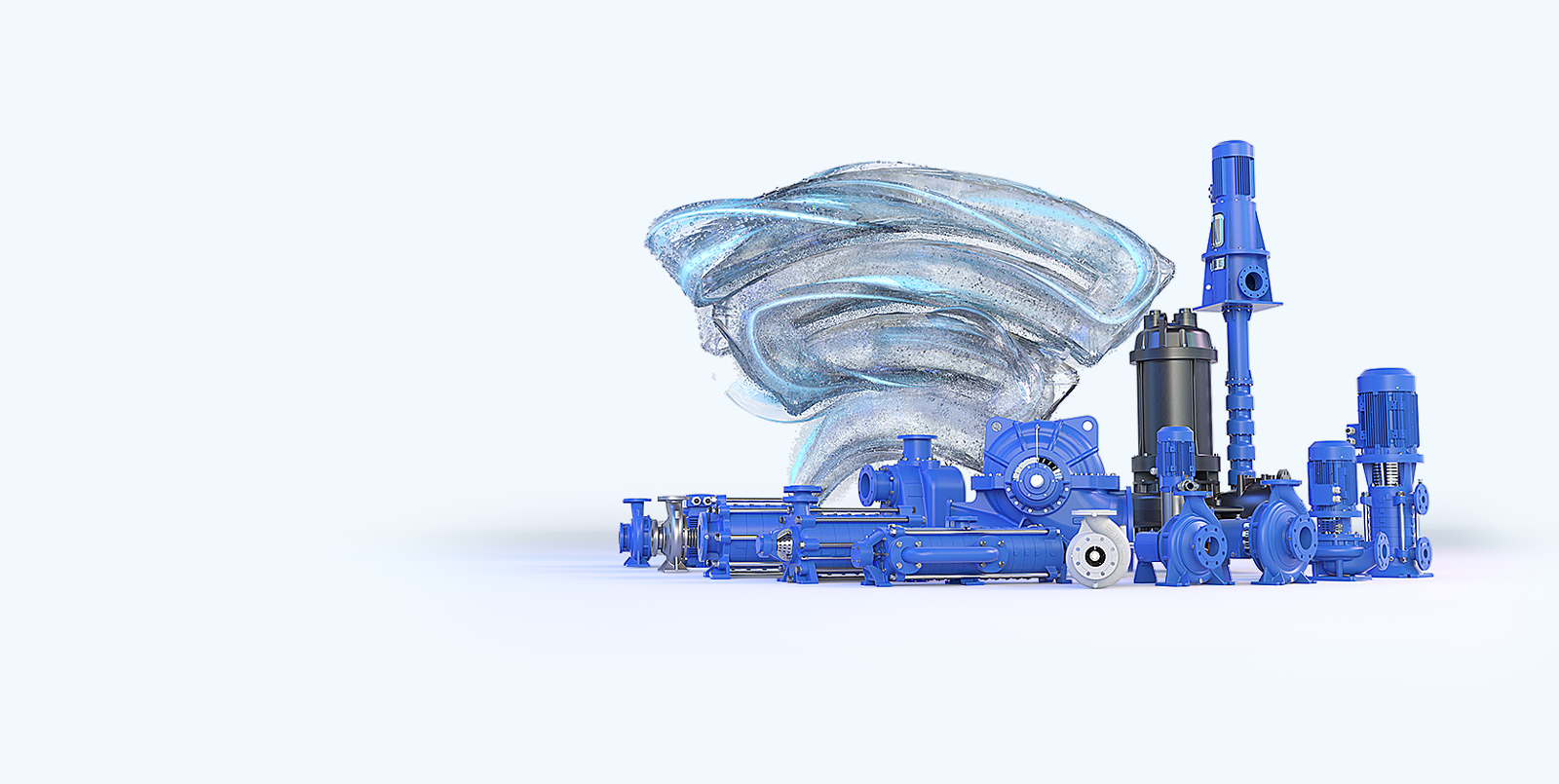

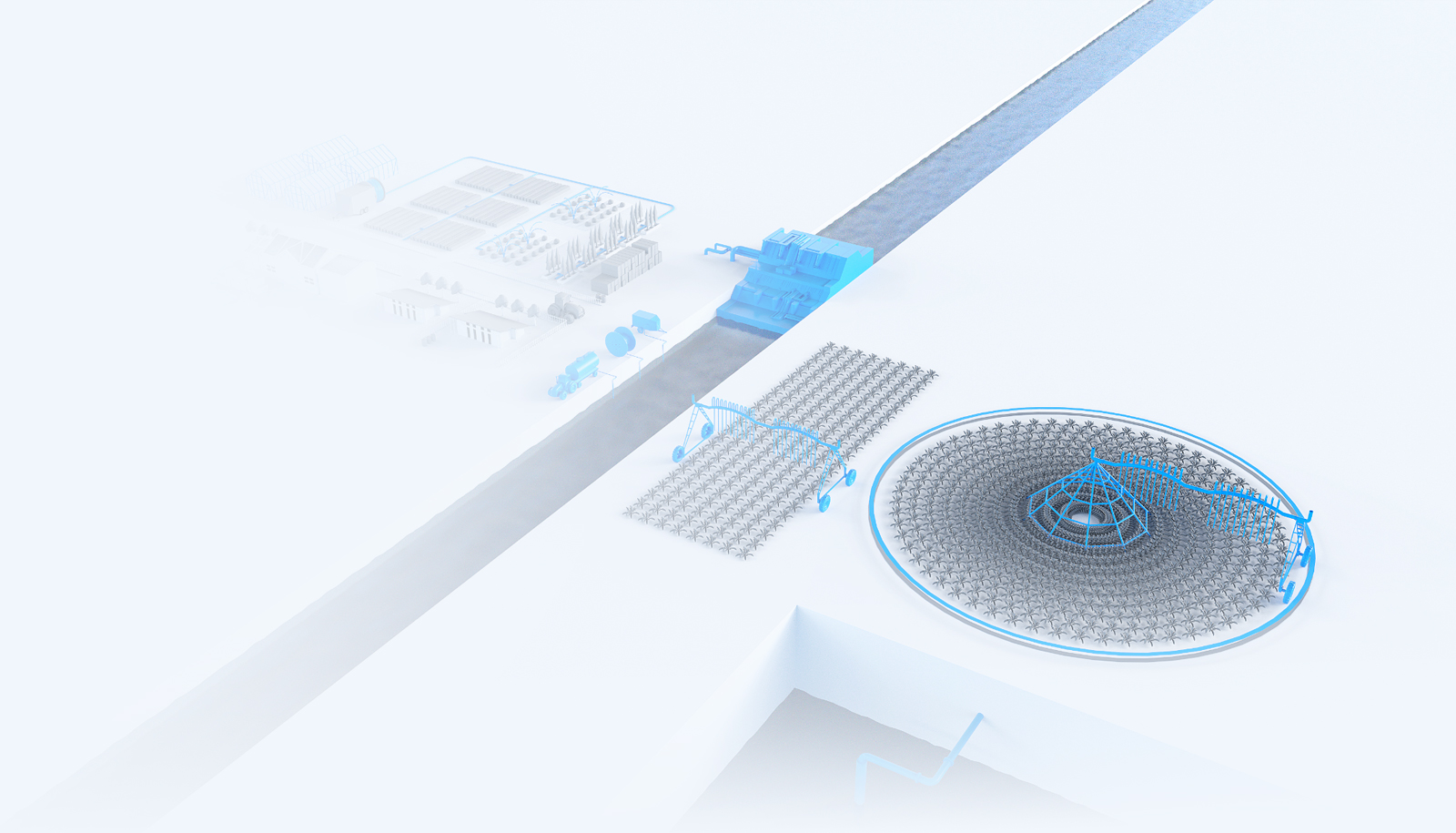

Yarım Asırlık Tecrübe!

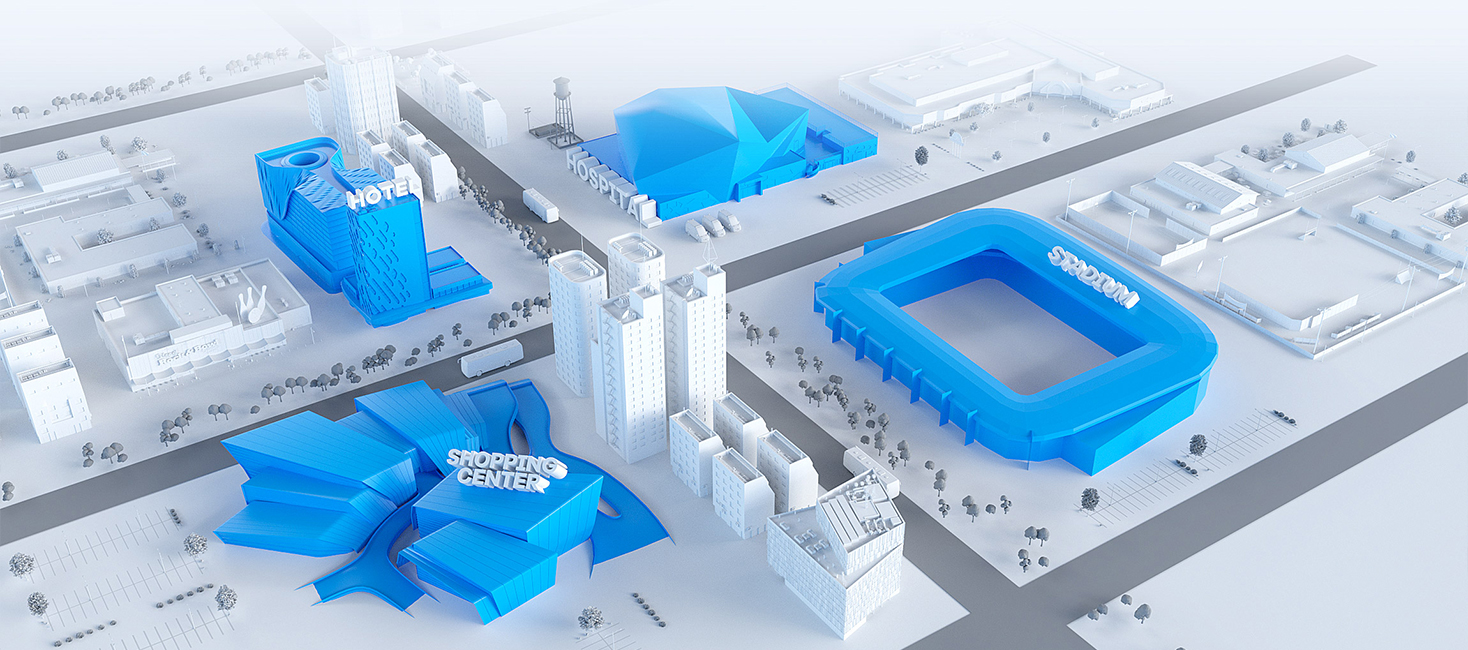

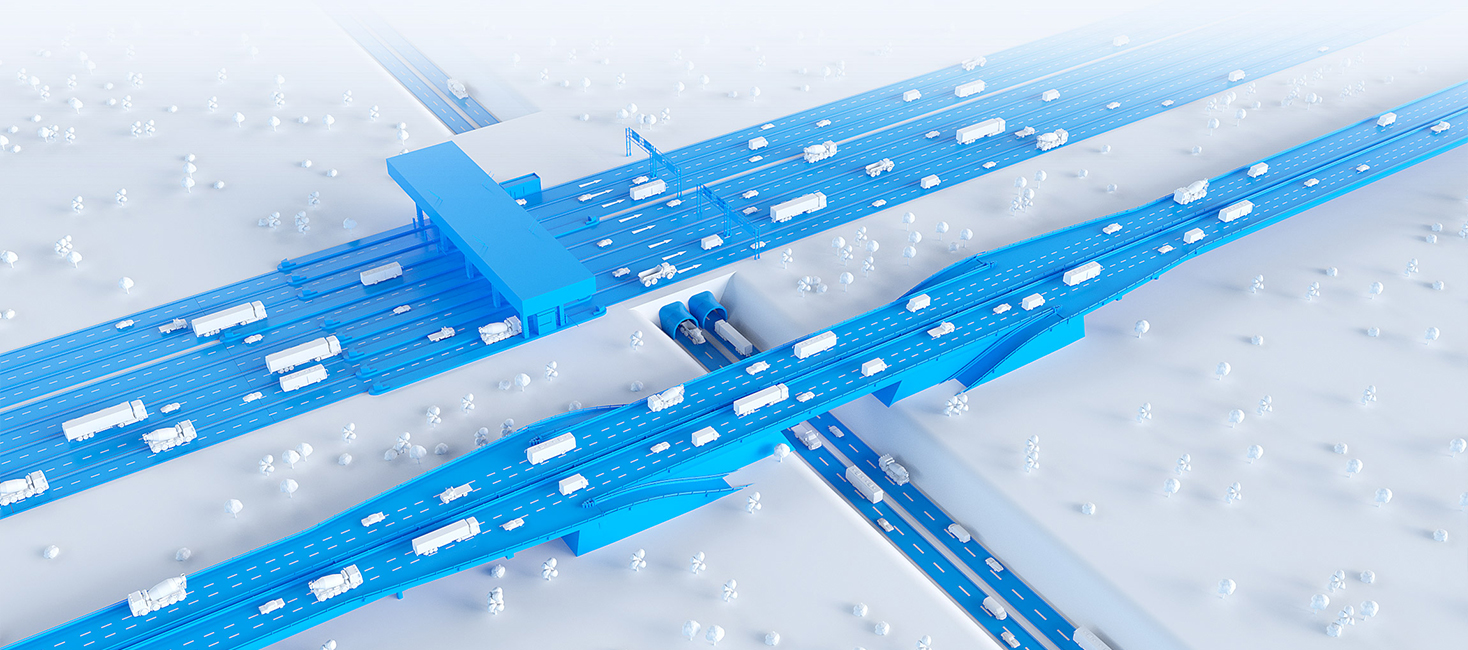

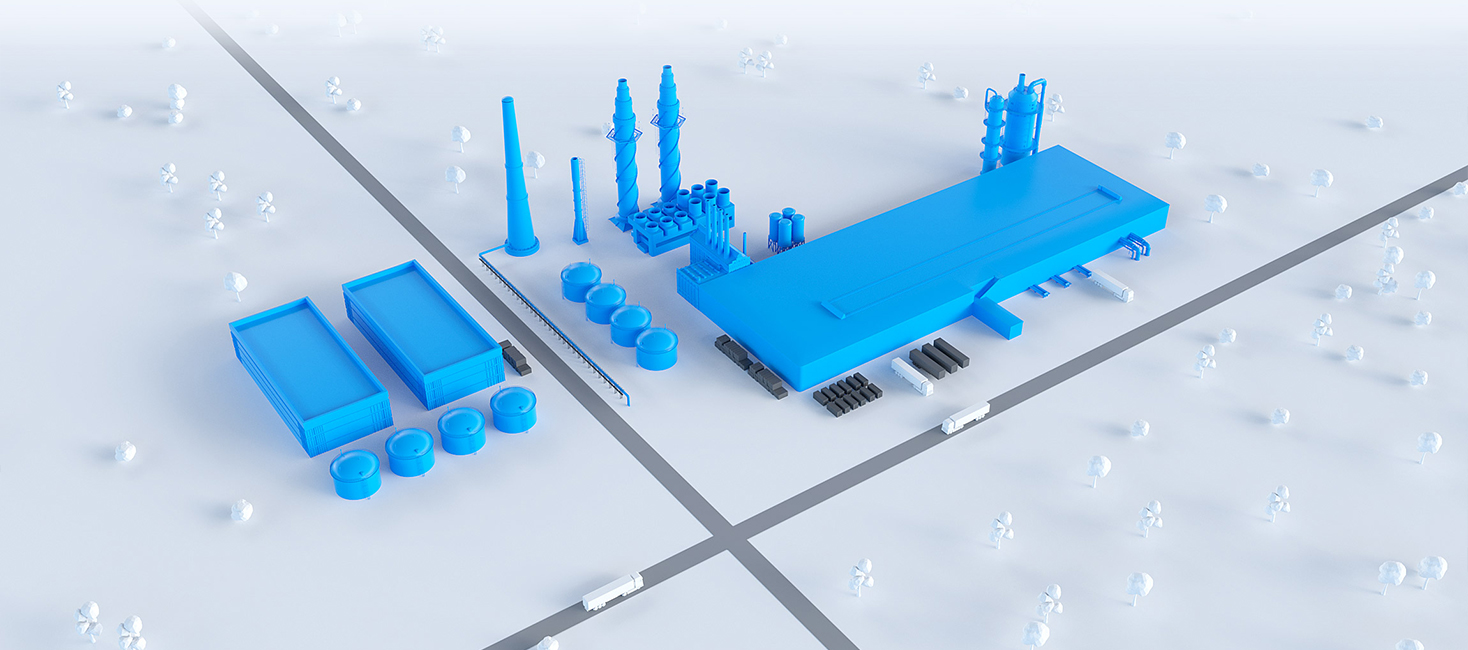

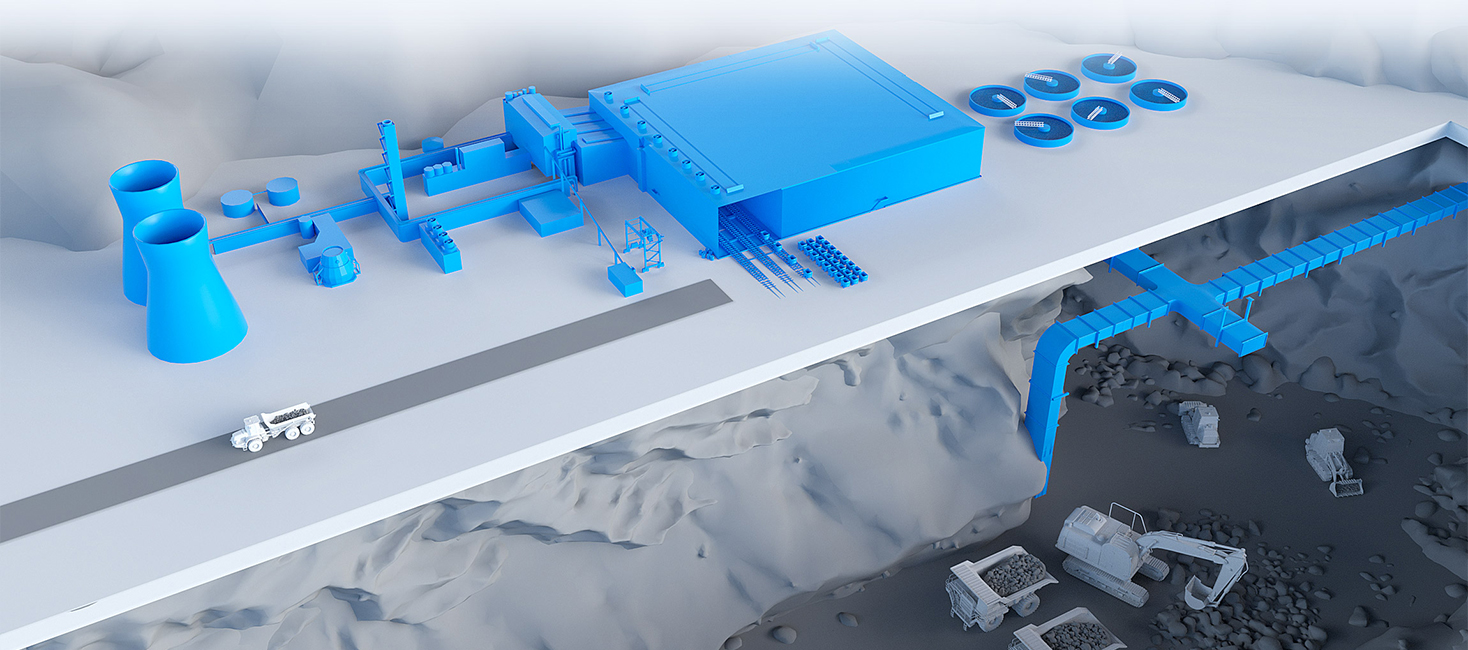

Yüksek Mühendislik Ve Yenilikçi Ürünler İle Endüstri Standartlarını Yükseltiyoruz.

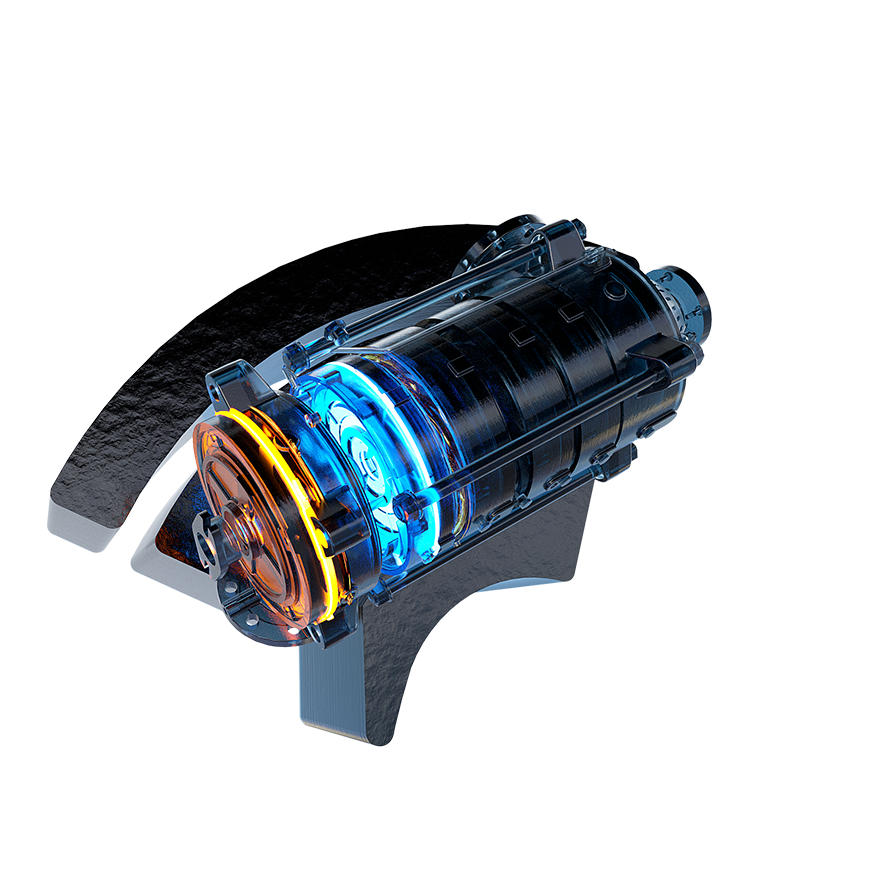

Seçim Yap

Seçim Yap